Aluminium 7449 Alloys, also known as UNS A97449, is a high-performance aluminum alloy recognized for its excellent mechanical properties and strength-to-weight ratio. It conforms to international standards such as DIN 3.4354 and EN AW-7449, ensuring quality and reliability in various applications.

Aluminium 7449 alloy is specifically designed for applications that require high strength, fatigue resistance, and toughness, making it suitable for aerospace and military applications, among others.

At Plus Metals, we supply Aluminium 7449 in plates, sheets, and custom sizes, ensuring fast delivery and full material traceability for aerospace-grade requirements.

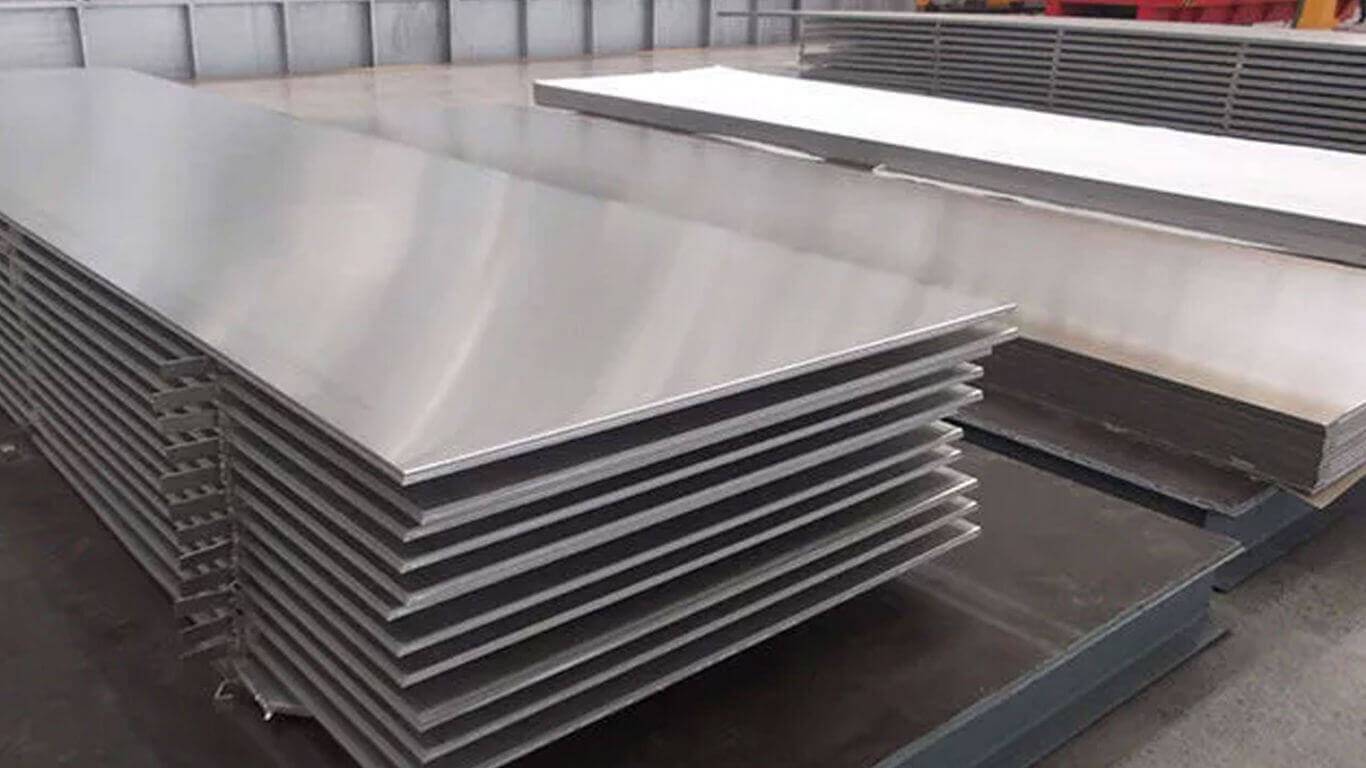

Aluminium 7449 Alloy Sheet | Plate

Aluminium 7449 Alloy sheets and plates are available in a variety of thicknesses and dimensions. These materials are essential for high-stress applications in the aerospace sector, where weight reduction and strength are critical.

Aluminium 7449 Alloy Round Bar | Rod

Aluminium 7449 Alloy round bars and rods are offered in various diameters and lengths. These products are crucial for precision machining and manufacturing components that must endure significant mechanical loads.

Aluminium 7449 Alloy Strip | Coil

Available in strips and coils, 7449 is suitable for applications requiring lightweight yet high-strength materials. These forms are often used in aerospace components and structural applications.

Aluminium 7449 Alloy Applications

- Aluminium 7449 Alloy is extensively used in aerospace applications, including airframe components, wing structures, and fuselage elements due to its high strength and low weight.

Aluminium 7449 Alloy Properties

- Tensile Strength: Approximately 590 MPa

- Density: About 2.83 g/cm³, providing a favorable strength-to-weight ratio for demanding applications.

- Thermal Conductivity: Roughly 130 W/m·K

- Corrosion Resistance: 7449 has good corrosion resistance, particularly when anodized, enhancing its durability in various environments.

Aluminium Machining 7449

- Cutting: 7449 can be cut using high-speed steel or carbide tools. Water jet or laser cutting is recommended for precise cuts.

- Drilling: Utilize carbide or cobalt drills for drilling 7449. Proper cooling and lubrication are crucial to maintain tool life and accuracy.

- Turning: Carbide inserts are preferred for turning 7449. Consistent cutting speeds and adequate cooling are essential for optimal results.

- Milling: Milling operations should employ carbide end mills with sufficient cooling to manage heat and maintain precision during processing.

- Grinding: For grinding 7449, use diamond or CBN wheels to achieve precise tolerances and a high-quality surface finish, with adequate cooling to prevent overheating.

Aluminium 7449 Alloys Chemical Composition

- Zinc (Zn): Min 7.7%, Max 8.7%

- Magnesium (Mg): Min 1.6%, Max 2.2%

- Copper (Cu): Min 1.6%, Max 2.0%

- Chromium (Cr): Max 0.05%

- Iron (Fe): Max 0.15%

- Silicon (Si): Max 0.12%

- Titanium (Ti): Max 0.06%

- Manganese (Mn): Max 0.10%

- Aluminum (Al): Balance

| Material | Form | Size Inches | SKU Number |

|---|---|---|---|

| ALUMINIUM 7449 | Sheet | Thickness: 0.020" to 0.500"; custom widths and lengths | ALUMINIUM7449-SHEET-0.125-12x12 |

| ALUMINIUM 7449 | Plate | Thickness: 0.500" and up; custom sizes | ALUMINIUM7449-PLATE-0.750-24x24 |

| ALUMINIUM 7449 | Bar/Rod | Diameter: 0.250" to several inches; length up to 36" or more | ALUMINIUM7449-BAR-1-36 |

| ALUMINIUM 7449 | Tube/Pipe | Diameter: 0.5" to several inches; custom wall thickness | ALUMINIUM7449-TUBE-1-0.125 |

| ALUMINIUM 7449 | Wire | Diameter: 0.010" to 0.250"; often supplied in coils | ALUMINIUM7449-WIRE-0.050-100 |

| ALUMINIUM 7449 | Custom Fabrications | Custom dimensions and shapes as required | ALUMINIUM7449-CUSTOM-FAB-001 |