The nuclear power sector depends on materials that can survive extreme temperatures, heavy radiation, and long operational cycles without failure. One of the most trusted materials for these demanding conditions is RENE 41 Alloy. Known for its high-temperature strength and excellent stability, RENE 41 Alloy has become a key material in building safe and efficient nuclear power systems.

This blog explains why RENE 41 Alloy is essential for nuclear power applications and how Plus Metals, a leading supplier of high-performance alloys in India, provides certified and reliable RENE 41 material for critical industries.

Understanding RENE 41 Alloy

RENE 41 Alloy is a nickel-based superalloy that provides exceptional mechanical strength at elevated temperatures. It contains nickel, chromium, cobalt, molybdenum, titanium, and aluminum elements that work together to give it:

- High tensile strength

- Resistance to thermal fatigue

- Excellent oxidation and corrosion resistance

- Long-term dimensional stability

Because nuclear operations run under extreme pressure and temperature, engineers require materials that do not deform, crack, or corrode. RENE 41 Alloy fits perfectly into this high-performance requirement.

Why RENE 41 Alloy Is Essential for Nuclear Power Applications

1. Outstanding High-Temperature Strength

Inside a nuclear reactor, components must operate continuously at high temperatures. Many metals weaken or deform over time, but RENE 41 Alloy maintains its strength even under sustained heat. This property is crucial for:

- Reactor structural supports

- Heat-resistant fasteners

- Fuel assembly components

- Radiation shielding fixtures

Its high-temperature stability promotes safety and durability within the nuclear environment.

2. Superior Resistance to Corrosion and Oxidation

The nuclear environment contains steam, chemically treated water, and reactive gases. Materials exposed to this environment must resist corrosion to prevent contamination and mechanical failure.

RENE 41 Alloy’s strong oxidation resistance protects it from:

- High-temperature steam

- Chemical corrosion

- Pressure-induced erosion

This ensures long-term reliability and durability of reactor components.

3. Excellent Performance Under Mechanical and Thermal Stress

Nuclear plants operate 24/7, which means reactor components face constant mechanical stress, vibration, and thermal cycling. RENE 41 Alloy has excellent:

- Creep resistance

- Fatigue resistance

- Stress rupture properties

These qualities help prevent cracks, distortions, and metal fatigue, making the material extremely reliable for continuous operations.

4. Radiation Resistance

Radiation can change the internal structure of metals, making them brittle over time. RENE 41 Alloy provides strong resistance to radiation effects, ensuring long service life in nuclear environments where materials must withstand years of exposure.

Real-World Performance and Proven Reliability

Beyond theoretical benefits, RENE 41 Alloy has a long record of use in industries like aerospace, gas turbines, defense, and nuclear engineering. This real-world performance builds confidence for engineers working on heavy-duty nuclear applications.

Naturally Integrated

At Plus Metals, we understand the critical nature of materials used in nuclear and high-temperature industries. That’s why we supply premium-grade RENE 41 Alloy that meets global quality standards.

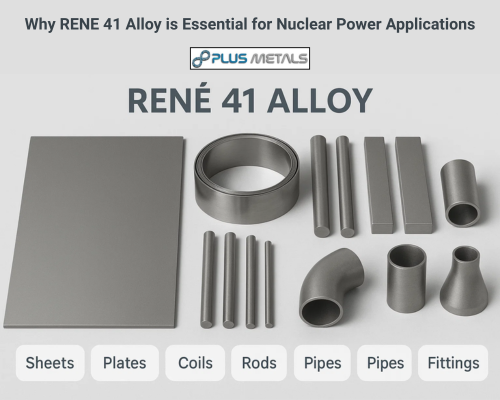

Wide Range of RENE 41 Alloy Products

We supply RENE 41 in:

- Sheets & Plates

- Bars & Rods

- Forged Components

- Custom Cut Sizes

- Export-grade Packaging

Certified & High-Quality Material

All RENE 41 Alloy supplied by Plus Metals is sourced from reliable global mills and comes with:

- Test certificates (EN 10204 3.1 / 3.2)

- Chemical composition reports

- Mechanical property documentation

This assures our customers of the authenticity and performance of the material.

Trusted by Nuclear, Aerospace & Defense Projects

Plus Metals has built strong relationships with companies that require precision and reliability. Our experience in high-performance alloys makes us the preferred supplier for industries that cannot compromise on quality.

Nationwide & Global Delivery

Whether you need 10 kg or multiple tons, we ensure:

- Fast dispatch

- Safe packaging

- On-time delivery across India and internationally

Expert Material Guidance

Choosing the right alloy is critical in nuclear applications. Our technical team assists engineers, procurement managers, and manufacturers with accurate guidance and specifications.

If you require RENE 41 Alloy for reactors, turbine components, or critical engineering systems, Plus Metals is ready to supply materials that deliver reliability and performance.

Conclusion

To summarise, RENE 41 Alloy is essential for nuclear power applications because of its high-temperature stability, corrosion resistance, stress durability, and exceptional resistance to radiation. Its proven performance makes it a trusted choice for nuclear engineers across the world.

Plus Metals ensures that industries receive high-quality, certified RENE 41 Alloy tailored to their project requirements, backed by professional service and timely delivery.

FAQs

1. Why is RENE 41 Alloy preferred in nuclear industries?

It offers superior high-temperature strength, corrosion resistance, and radiation stability.

2. What forms of RENE 41 Alloy does Plus Metals supply?

Sheets, plates, rods, bars, forged parts, and custom sizes.

3. Can Plus Metals supply RENE 41 Alloy with test certificates?

All materials come with authentic MTCs and chemical composition reports.

4. Does RENE 41 Alloy resist radiation damage?

It remains stable and does not easily become brittle under long-term radiation.

5. Can RENE 41 be used in aerospace?

Absolutely. It is widely used in turbine engines, exhaust systems, and high-temperature applications.