Modern industries that operate under extreme heat and pressure depend heavily on materials that can perform without failure. Turbines, reactors, and thermal systems are exposed to continuous high temperatures, corrosive environments, and mechanical stress. For such demanding conditions, high temperature alloys are the most reliable material choice.

When industries plan to buy high temperature alloys for turbines, reactors & thermal systems, they are not just purchasing metal—they are investing in safety, efficiency, and long-term performance.

Understanding High Temperature Alloys

High temperature alloys are specially designed metallic materials that retain strength, stability, and corrosion resistance at elevated temperatures. Unlike standard carbon steel or low-alloy steel, these alloys do not weaken, deform, or oxidize easily when exposed to extreme heat.

These alloys are typically based on:

- Nickel-based alloys

- Iron-nickel alloys

- Chromium-rich heat resistant alloys

They are engineered to resist:

- Creep and thermal fatigue

- Oxidation and scaling

- Corrosion under high heat

This makes them essential in critical industrial systems where failure is not an option.

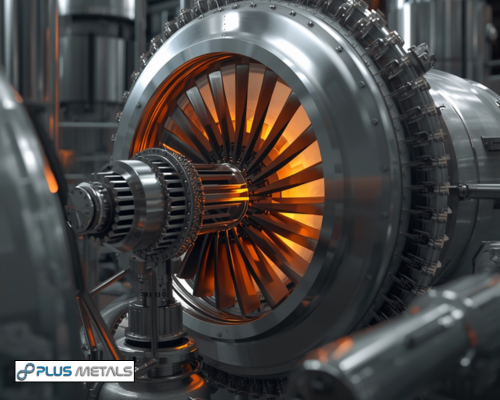

Importance of High Temperature Alloys in Turbines

Turbines operate under intense heat, rotational force, and pressure. Gas turbines, steam turbines, and power-generation turbines require materials that can withstand continuous thermal cycling.

High temperature alloys are commonly used in:

- Turbine blades and rotors

- Combustion chambers

- Exhaust and heat recovery systems

- High-strength fasteners

Without these alloys, turbines would suffer from rapid wear, cracking, or loss of efficiency. This is why manufacturers carefully select materials before they buy high temperature alloys for turbines, reactors & thermal systems.

Role of High Temperature Alloys in Reactors

Reactors in chemical, petrochemical, and nuclear industries face extreme operational challenges. These systems deal with high temperatures, internal pressure, and aggressive chemicals simultaneously.

High temperature alloys help reactors by:

- Maintaining mechanical strength at high heat

- Resisting oxidation and chemical attack

- Preventing material degradation over long operating cycles

They are widely used in reactor vessels, internal components, heat exchangers, and high-pressure piping systems.

Use of High Temperature Alloys in Thermal Systems

Thermal systems such as furnaces, boilers, kilns, and heat treatment units run at consistently high temperatures for long durations. Standard metals fail quickly under such conditions.

High temperature alloys are preferred for:

- Furnace linings and supports

- Radiant tubes and burners

- Heating elements and shields

- Thermal expansion–resistant components

When industries buy high temperature alloys for turbines, reactors & thermal systems, thermal system reliability is one of the main reasons behind the investment.

Key Properties That Make These Alloys Reliable

- Excellent strength retention at high temperatures

- Resistance to creep and thermal fatigue

- High oxidation and corrosion resistance

- Long service life with minimal maintenance

- Dimensional stability under thermal stress

Common Product Forms of High Temperature Alloys

- Sheets and plates

- Pipes and tubes

- Rods, bars, and wires

- Rings, flanges, and fittings

- Custom-machined components

The ability to source the correct form and size from a trusted supplier is critical for project success.

Plus Metals – Reliable Supplier of High Temperature Alloys

Plus Metals is a trusted manufacturer, supplier, and exporter of high temperature alloys, serving customers across India and international markets. With strong industry experience and a wide product portfolio, Plus Metals supports critical applications where performance and reliability matter most.

If you are planning to buy high temperature alloys for turbines, reactors & thermal systems, Plus Metals offers both technical expertise and dependable supply.

What Plus Metals Supplies

Product Supply Includes:

- High temperature alloy plates and sheets

- Pipes and tubes for heat and pressure applications

- Bars, rods, and wires

- Custom cut sizes as per drawings

- Bulk supply for large industrial projects

All materials are supplied with proper testing, certification, and traceability.

Quality Standards Followed by Plus Metals

Quality is critical when dealing with high temperature applications. Plus Metals ensures that every product meets international standards, including:

- ASTM

- ASME

- EN

- DIN

- Other global specifications as required

Each batch is tested for chemical composition, mechanical properties, and dimensional accuracy before dispatch.

Industries Served by Plus Metals

- Power generation plants

- Oil and gas processing units

- Chemical and petrochemical industries

- Thermal equipment manufacturers

- Aerospace and heavy engineering sectors

This wide industry exposure allows Plus Metals to understand real-world operating challenges and recommend suitable materials.

Why Buyers Prefer Plus Metals

- Consistent product quality

- Competitive pricing

- Reliable delivery timelines

- Technical support in alloy selection

- Strong exporter reputation from India

When you buy high temperature alloys for turbines, reactors & thermal systems from Plus Metals, you gain a dependable long-term supply partner.

Buy Now from Plus Metals

Choosing the right supplier is as important as choosing the right alloy. Whether you need standard sizes or custom specifications, Plus Metals is equipped to deliver quality materials on time.

Buy high temperature alloys now

Visit: Plus Metals

Contact Plus Metals today for quotations, datasheets, and expert guidance

Frequently Asked Questions (FAQ)

Q1. What temperature range do high temperature alloys support?

Most high temperature alloys perform efficiently between 600°C and 1100°C, depending on the grade.

Q2. Can Plus Metals supply custom sizes?

Yes, Plus Metals provides custom cut sizes and bulk quantities based on project requirements.

Q3. Are these alloys suitable for corrosive environments?

Yes, many high temperature alloys offer excellent resistance to oxidation and chemical corrosion.

Q4. Does Plus Metals export high temperature alloys?

Yes, Plus Metals is an experienced exporter supplying global industrial markets.

Q5. How can I place an order?

You can visit Plus Metals or contact the sales team directly for fast assistance.